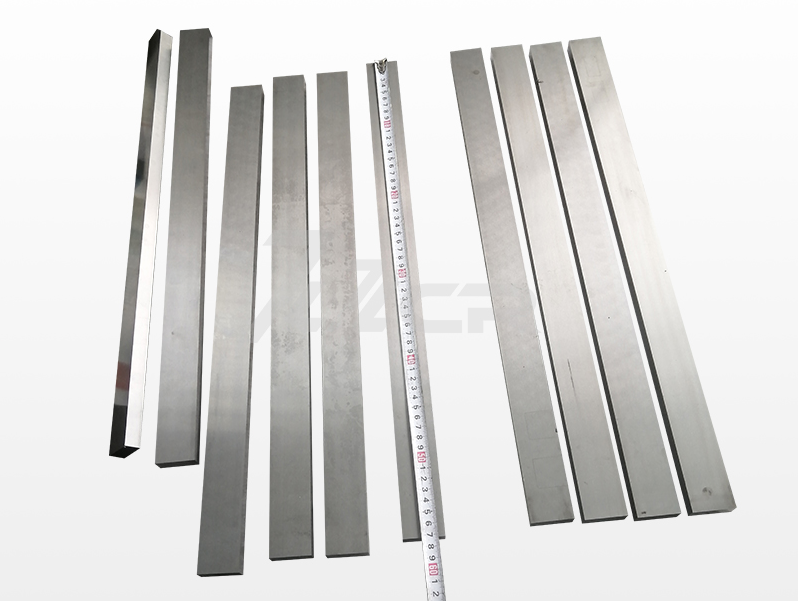

Mzere wa Tungsten Carbide umapangidwa makamaka ndi cangsten carbide ndi cobalt ufa wosakanizidwa ndi pubala, zomwe zimagwiritsidwa ntchito ndi zopondera za wc ndi com.

Chimodzi mwazinthu zambiri za mbewa zotumphukira, zimatchedwa chifukwa cha kuchuluka kwake kwa mbale (kapena mabwalo), omwe amadziwikanso kuti ma tungesten Grobide / mbale. Mzere wa Tungsten Carbide ali ndi kuvala bwino, kuvala bwino kukana, mphamvu yayikulu yolemetsa, kukhazikika kwamphamvu kwa maxidation kukana), mapangidwe amagetsi ndi mabwana ake.

Zifukwa zake ndi zitikumasulisilaMzere kwa ma cangsten? Chuangrui Carbide ayankha pambuyo pake:

.

(2)Kumasulisilazidzachitikanso pamene wothandizila sanasankhidwe ndikugwiritsa ntchito molakwika,kumasulisilaPhenomenon amapezeka.

(3) Kutentha koyenera kuyenera kukhala 30 ~ 50 ° C pamwamba pa chitsulo chosalala, ndikumasulisilazidzachitika ngati matenthedwe ali okwera kwambiri kapena otsika kwambiri. Kutenthetsa kwambiri kumatha kuyambitsa makwerero mu ma weld. Kugwiritsa ntchito zitsulo zokhala ndi zitsulo zokhala ndi zitsulo kumapereka mawola abuluu kapena oyera. Mafuta ophulikawo akakhala otsika kwambiri, kuwotchera tating'onoting'ono kwambiri kudzapangidwa, ndipo mkati mwa weld idzakutidwa ndi kapangidwe kake ndi zopsereza. Zinthu ziwiri pamwambazi zimachepetsa mphamvu ya weld, ndipo ndikosavuta kuimwa msanga kapena kugwiritsidwa ntchito.

Post Nthawi: Aug-28-2024